Series

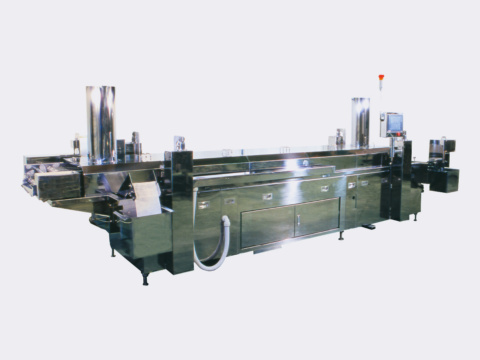

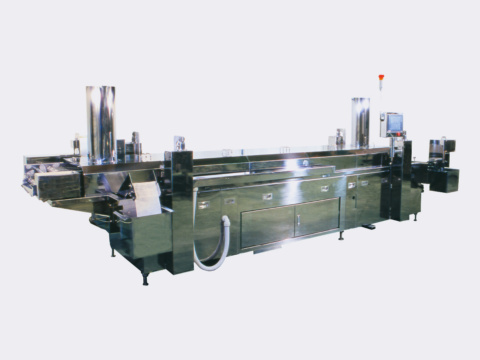

SM-FW600-5000DHN Gas-heated Fryer

The SM-FW600-5000DHN is a large, gas-heated, continuous fryer.

- The machine delivers higher heat efficiency than previous models thanks to its use of a special combustion gas circulating mechanism.

- We can propose the best possible conveyor system for the food product being fried.

- The machine provides excellent cleanability thanks to a conveyor that can be raised during cleaning and an oil tank with a flat bottom.

- It uses an oil circulating mechanism based on a special, proprietary pump.

This system keeps oil temperature at the entrance, where there’s a large temperature drop, stable.

A continuous debris removal system located at the pump oil inlet keeps the oil clean.

- All hoods can be removed for cleaning.

- Frying time settings can be adjusted easily using an inverter.

- There’s a scraper-type debris removal mechanism at the machine entrance to complement system at the oil intake.

- The machine comes standard with a safety mechanism that prevents it from being operated without oil.

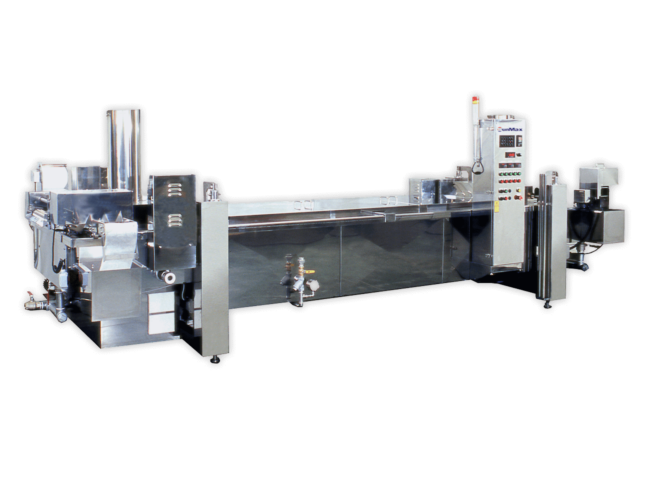

SM-FW600-5000ES Electric Fryer

The SM-FW600-5000ES is a large, electric continuous fryer.

- The electric heater is submerged in oil for high efficiency.

- We can propose the best possible conveyor system for the food product being fried.

- The machine provides excellent cleanability thanks to a conveyor and electric heater that can be raised during cleaning and an oil tank with a flat bottom.

- The exhaust gas-free design is easy on the environment and requires no exhaust gas ducting.

- The machine uses an oil circulating mechanism based on a special, proprietary SunMax pump.

This system keeps oil temperature at the entrance, where there’s a large temperature drop, stable.

A continuous debris removal system located at the pump oil inlet keeps the oil clean.

- All hoods can be removed for cleaning.

- Frying time settings can be adjusted using an inverter.

- There’s a scraper-type debris removal mechanism at the machine entrance to complement system at the oil intake.

- The machine comes standard with a safety mechanism that prevents it from being operated without oil.

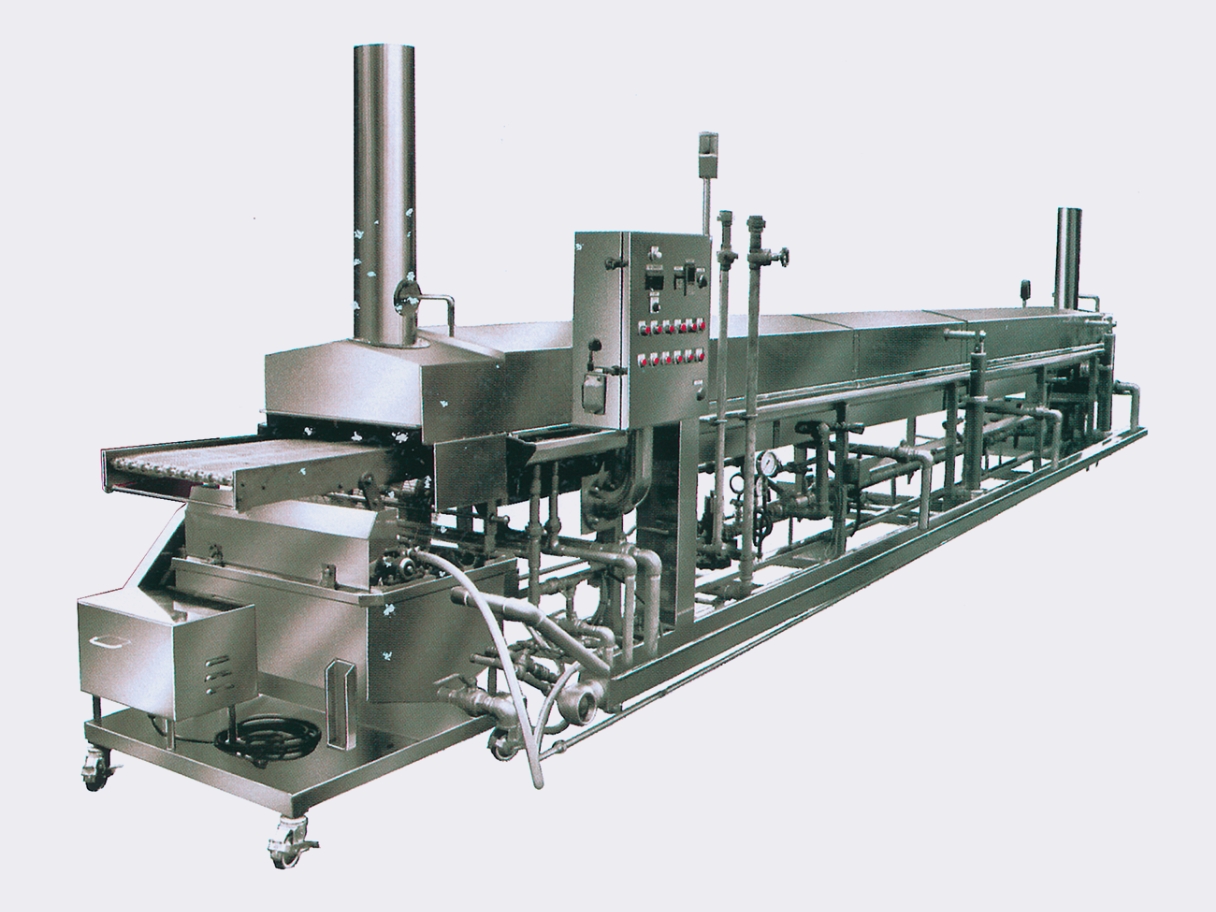

SM-FW600-5000HX Steam-heated Fryer

The SM-FW600-5000HX is a large, steam-heated continuous fryer.

- Heat is transferred from high-pressure steam to the oil by means of a high-efficiency heat exchanger.

- At about 200°C, the low temperature of the heat source’s high-pressure steam reduces oil damage, and the lack of flame means the machine is safe to use.

- The exhaust gas-free design is easy on the environment and requires no exhaust gas ducting.

- We can propose the best possible conveyor system for the food product being fried.

- The machine provides excellent cleanability thanks to a conveyor that can be raised during cleaning and an oil tank with a flat bottom.

- It uses a non-seal pump that doesn’t need cooling water to circulate the oil.

This system keeps oil temperature at the entrance, where there’s a large temperature drop, stable.

A continuous debris removal system located at the pump oil inlet keeps the oil clean.

- All hoods can be removed for cleaning.

- Frying time settings can be adjusted using an inverter.

- There’s a scraper-type debris removal mechanism at the machine entrance to complement system at the oil intake.

- The machine comes standard with a safety mechanism that prevents it from being operated without oil.

SM-TK-1500 Storage Tank

This oil stock tank is used when cleaning the fryer.

- It’s designed to store oil temporarily after filtering.

- An insulated design keeps the oil warm.

- It can be installed on top of the fryer to save space.

- A cleaning hose can be attached so that the fryer’s conveyor and oil tank can be rinsed with oil. (Option)

- When using hardened oil, the oil can be kept warm with an electric heater or steam pipe. (Option)

Grease Separator

This system uses a water membrane (Bubbling Power) to efficiently remove fat and oil from exhaust containing oil smoke.

- It delivers an oil and fat removal rate of at least 90%.

- Oil and fat in cooking process exhaust air can be removed with a high level of efficiency by passing it through a water membrane (Bubbling Power).

- The water membrane (Bubbling Power) reduces unpleasant odors in exhaust air along with oil and fat.

- The system also improves safety since it lowers the exhaust air temperature in exhaust ducts.